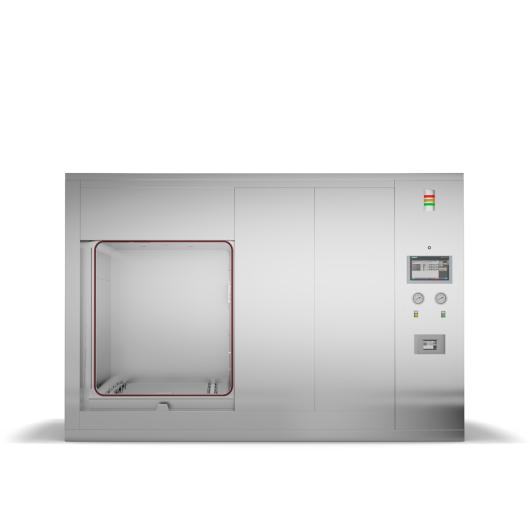

Pharma grade saturated steam sterilizers

Steelco AV series pharmaceutical grade saturated steam sterilizers are a fundamental part of the process used to render an object free from viable infectious agents, including viruses and bacterial spores. The vast experience acquired at Steelco Group in over thirty years of activity enables us to provide a highly diversified saturated steam sterilizer to meet the requirements of the most varied applications.

Built to a very high standard, each unit is tailored to the customer’s specifications. AV series is used to sterilize with clean/pure saturated steam materials such as vials, bottles, glass items, fabric materials, sealed or vented containers, rubber parts, machine parts, filters, etc.

The devices feature chamber volumes from 195 to 10.000 liters (7 to 353 cu ft) in several dimensions with configurable options. The AV Series of steam sterilizers are high-performing, reliable, and easy to use. Its sterilization cycle has been specifically designed to minimize time and energy consumption while maximizing efficiency and throughput.

The AV Series of saturated steam sterilizers is designed, manufactured, validated, and documented according to the latest global practices and standards to facilitate customers’ compliance with current Good Manufacturing Practices (cGMPs). Steelco pharma grade machines comply with the applicable requirements of the following regulations and industry accepted guidelines:

- cGMP

- GAMP 5

- FDA Regulation 21 CFR Part 11, 211, 820

- Eudralex

- ASME BPE

- PDA Technical Report

- European and US Pharmacopeia

- ISPE Guidelines

- UL and CSA (on demand)